SCT STRAW: Commitment with Food Safety in Plastic Products

SCT STRAW has over 35 years of experience in plastic extrusion, with a longstanding commitment with food safety in products such as hard candy sticks and other packaging elements in contact with food. Therefore, we steadfastly adhere to Regulation (EU) No. 10/2011.

This regulation provides a list of authorized substances for food contact. SCT STRAW consistently selects raw materials based on this list to ensure the safety and health of consumers.

Subsequently, we comply with specific migration limits by conducting laboratory tests to ensure compliance with the standard in every aspect.

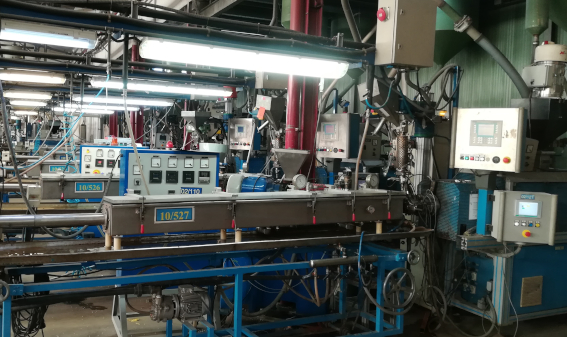

From a manufacturing perspective, our machines feature external metal control systems. We place a magnet in the extruder hopper to attract any ferrous elements near the raw material. Additionally, a sensor at the line's entrance checks for metal presence, automatically halting production if any is detected.

In our production lines, we maintain a strict separation between food and non-food products in terms of water usage. Water from non-food products is never used for food products, ensuring compliance with quality standards and preventing contamination.

The packaging used at SCT STRAW is designed to avoid transferring harmful substances to future food-contact products. It also protects against contamination, moisture, and other factors that could affect product quality and shelf life.

Thanks to our stringent safety measures, we can manufacture a range of products, from food packaging like hard candy sticks to hygiene products like perfume tubes and even specialized items for animals, such as insemination tubes. This ensures full legal compliance for our plastic products, endorsing excellence in materials and processes.

.JPG)